Thank you Carl!

Final stage, the Indexing Plate.Yesterday, having diverted my energies to other things, I am trying to overcome my D3 battery issue. While waiting for eBay to deliver the bits I feel could provide the solution, I thought I better get on and do the final machining stage of the pano head, the indexing plate.

I made the ball retaining sleeve from a little scrap brass, a quarter inch ball bearing and a spring. It was very tricky to drill a tight hole for the ball, yet reduce the diameter to prevent the ball escaping AND have sufficient ball protruding, to engage as fully as possible with the indexing plate.

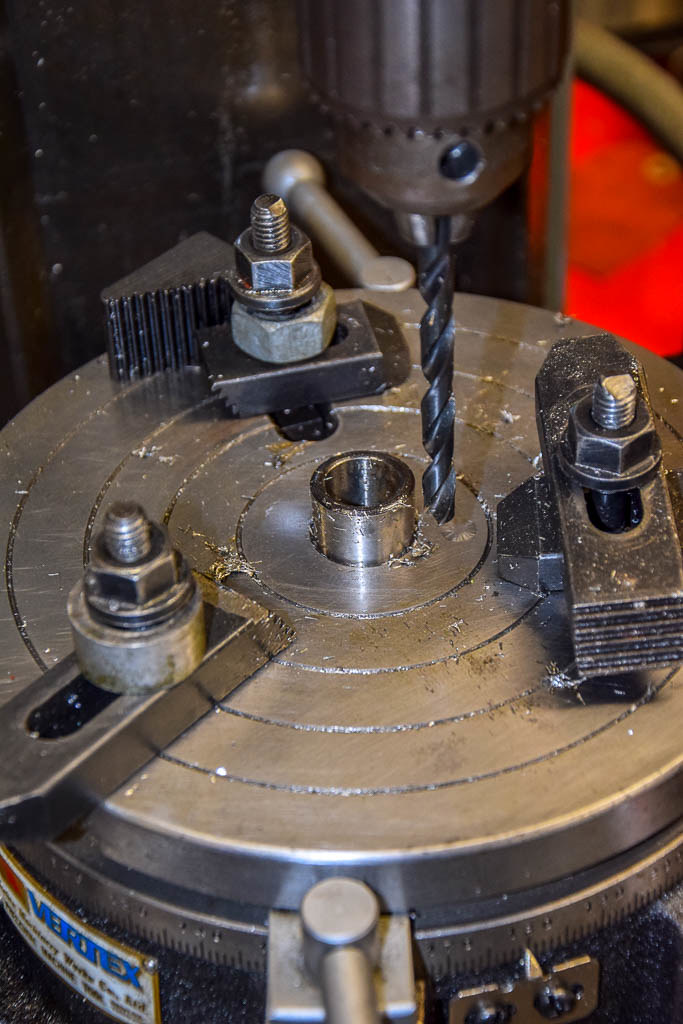

I was in some trepidation about it, it's a tiny part of the project but a crucial one. I rang my friend and discussed the options, either on his milling machine or my lathe... In the end we decided it would be better to use an indexing head on his milling machine, so I went over to his place. I was too focused on the task to remember to photograph the actual milling but I do have a photo of the setup, taken afterwards.

The setup was easy, easier than I expected, but the mill doesn't have a quill, the only way of driving the drill into the metal is by raising the table. The table is very heavy (it takes two hands to wind it) and somewhat awkward to raise accurately. I set the depth gauge so the first cut could be repeated but all the cuts are slightly different depths.

With the relatively flat angle of the drill V, slight differences in depth are magnified in the angle of the cut, the errors are doubled because the slack is diameter, not radius, back and forward.

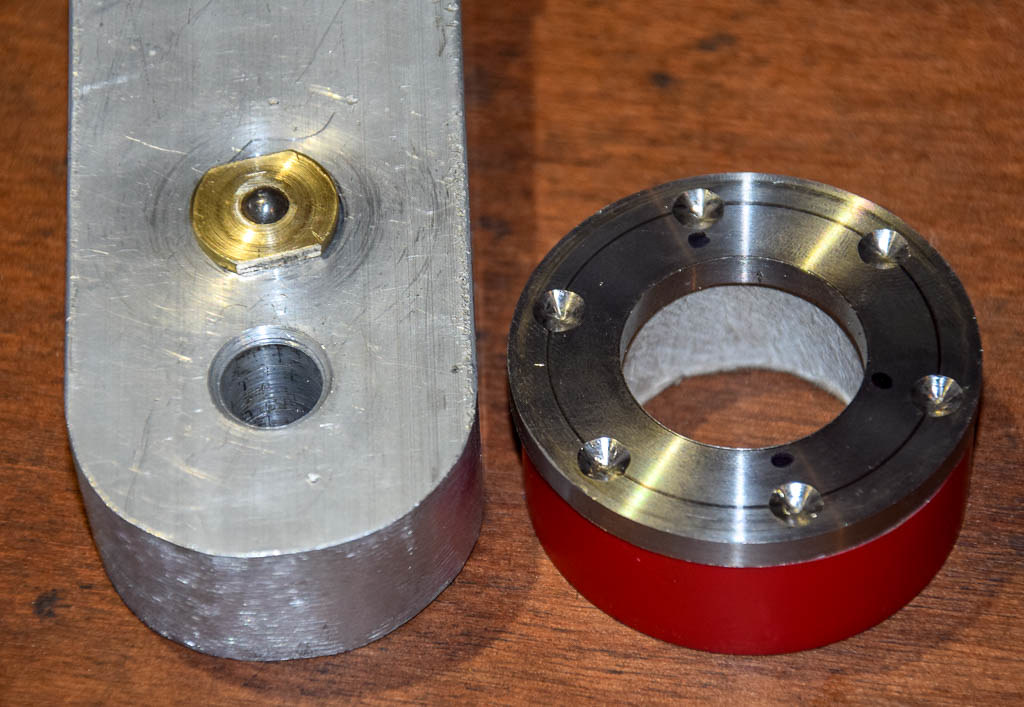

The result is that three of the locations are positive, click in, nice and tight, no movement. The other three are loose, one very loose.

The ones with the black dots are the loose ones.

Somewhat disappointed, on my way home I was trying to think of a solution, since accurate, positive location is crucial to the entire thing. This morning playing around with it and considering the alternatives, I have finally decided to drill the holes right through, at a smaller size, that way I retain the accurate indexing of 60º and the pitch circle radius of the holes, which I think is spot on. I will use a slightly smaller drill than may be indicated, which gives me the option to enlarge the holes if needs be, it's not easy to make them smaller...

Just waiting for it to get a little less cold outside, is raining too, a proper gloomy February day, roll on spring and summer!