Much progress has been made since my last post.

I have essentially completed the machining of the main parts with the exception of the detent ring for the click positioning of the rotation, for the D3, 16mm Fisheye combination that will be six clicks @ 60º.

Part of the delay has been clearing my shed to allow the re-assembly of my own lathe, making this pano head is very time consuming and although my friend is very accommodating it entails a 60 mile+ round trip to visit him and also fitting in with his spare time, so having completed what needed his larger lathe, I decided I had to get my own lathe working. This was my driving motivation! The lathe had been dismantled to make transportation easier. I got the lathe back together pretty well but when I started the freshly overhauled motor, it ran backwards!!!

I swapped the two starter winding leads and normal rotation resumed much to my relief and pleasure.

All these illustrations have been made using my D3300 and the rough 'workshop' badly gouged 18-105 VR lens.

This is the start of creating a groove to enable the ring to be cut from the disk.

The moment the ring separated from the central disk, a moment of tension because I was unsure how it would behave. Near the bottom is the special tool I had made to cut the grooves for the Arca clamps.

A close up of the tool cutting the groove.

The ring mounted on a face plate, using three nodal rails to hold it. This was to clean up the inner face of the ring after it was cut from the disk.

The boring tool used to clean up the ring.

Machining the mounting clamps from eBay which I will use to mount the curved rail. This was done on my friends Milling machine. I clamped an Arca rail to the machine bed then clamped the bracket clamp to the rail, that helped to make the repeatability to machine the second bracket clamp. Notice the spirit level, we machined about 1mm of the plastic and it survived! Not that it mattered, normally for this purpose it's orientated vertically, so of little use.

Here is the (almost) finished product.

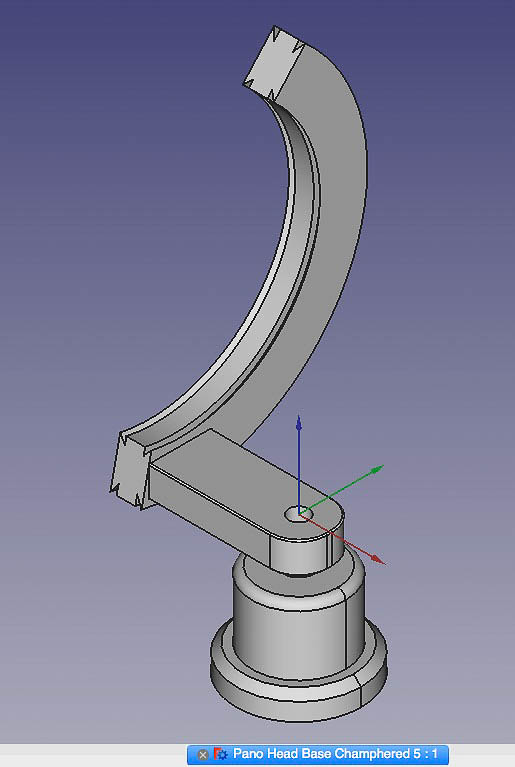

For comparison the 3D CAD drawing, with the exception of adding the clamp to mount the ring which was an afterthought which made mounting and aligning the ring a doddle.

And...

I intend to have the aluminium parts anodised black, I also intend to calibrate the ring with angles of at least 30º to help repeatability when setting the camera to face up, level or down, which I think will be 30º above and below level.

I have tested the 'nodal' point for the Nikkor 16mm f2.8 Fisheye. The point of zero parallax error, according to my somewhat rough tests, it is perfectly aligned, there appears to be no parallax error, vertically or horizontally.